Reducing operational costs is a constant challenge for businesses in warehousing and logistics. Whether you’re managing a single warehouse or a complex distribution network, inefficiencies can quickly erode profitability. This is where a Warehouse Management System (WMS) proves invaluable for WMS reducing operational costs. By streamlining workflows, automating manual tasks, and optimising inventory management, a WMS not only enhances operational efficiency but also delivers measurable cost savings. Furthermore, real-time data analytics allow businesses to identify areas for improvement and make informed decisions, ultimately leading to better resource allocation and increased productivity. Implementing a WMS empowers organizations to stay competitive in a rapidly evolving market while ensuring they meet customer demands efficiently.

For Australian businesses, the benefits of WMS are especially significant. With the unique logistical challenges posed by vast distances and diverse market demands, managing costs effectively is critical. A WMS tackles these challenges by providing real-time insights, integrating with existing systems, and reducing errors, enabling businesses to operate leaner and smarter while WMS reducing operational costs. Additionally, the automation of routine tasks frees up staff to focus on higher-value activities, enhancing overall productivity. By improving order accuracy and fulfillment speed, a WMS also boosts customer satisfaction, fostering loyalty in a competitive market.

Key Ways WMS Reduces Operational Costs

| Cost Area | How WMS Reduces Costs |

|---|---|

| Labour Costs | Automates repetitive tasks, improves picking accuracy, and optimises worker productivity. |

| Inventory Costs | Reduces overstocking and stockouts through real-time tracking and demand forecasting. |

| Order Fulfilment Costs | Streamlines picking, packing, and shipping processes to ensure timely and accurate deliveries. |

| Storage Costs | Optimises warehouse layouts to maximise available space and minimise wastage. |

| Return Management Costs | Automates returns processing, ensuring efficient restocking and accurate inventory updates. |

| IT Infrastructure Costs | Cloud-based WMS reduces the need for expensive on-site IT infrastructure and maintenance. |

Enhancing Labour Productivity Through WMS

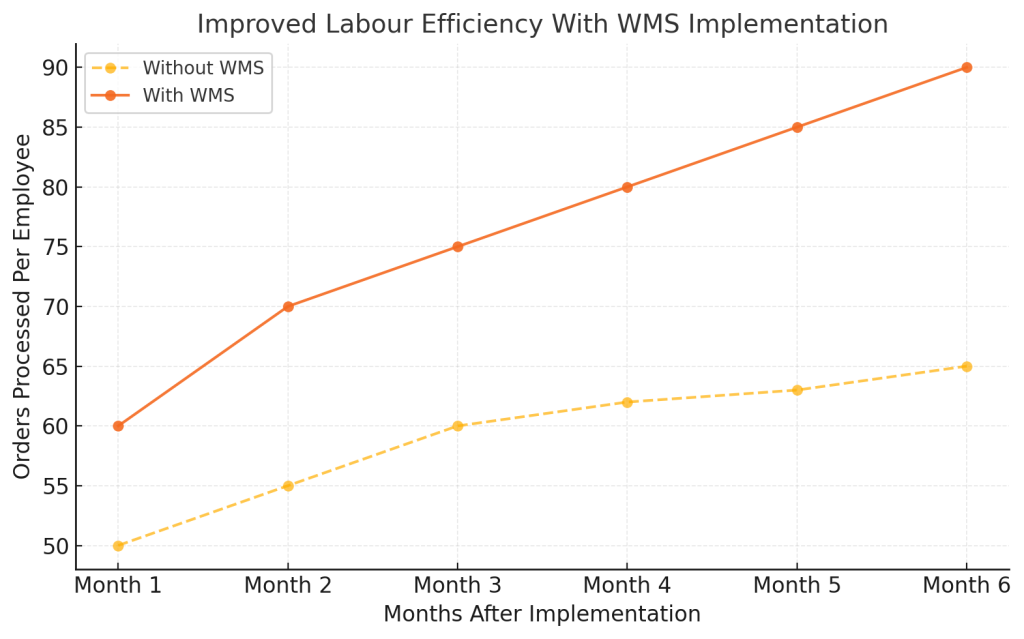

Labour costs often constitute a significant portion of operational expenses in warehousing. A Warehouse Management System (WMS) addresses this challenge by automating repetitive tasks and optimising workflows, enabling businesses to do more with fewer resources. Tasks like inventory counting, order picking, and packing become faster and more accurate, reducing the need for manual intervention and lowering error rates. Furthermore, the real-time data provided by a WMS allows for better workforce management, ensuring that staff are allocated efficiently based on demand fluctuations. This enhanced labour management not only maximizes productivity but also contributes to WMS reducing operational costs overall, making operations more sustainable in the long run.

For instance, features such as barcode scanning, RFID integration, and pick-path optimisation ensure workers follow the most efficient routes within the warehouse. This not only minimises travel time but also allows employees to process more orders in less time. Furthermore, WMS automation can reduce reliance on temporary labour during peak seasons, providing consistent cost savings year-round. By improving accuracy in order fulfillment, businesses can also enhance customer satisfaction and build loyalty, leading to increased sales over time. Additionally, the insights gained from data analytics enable managers to make informed decisions about staffing and resource allocation, further improving operational efficiency.

Optimising Costs Across Additional Areas

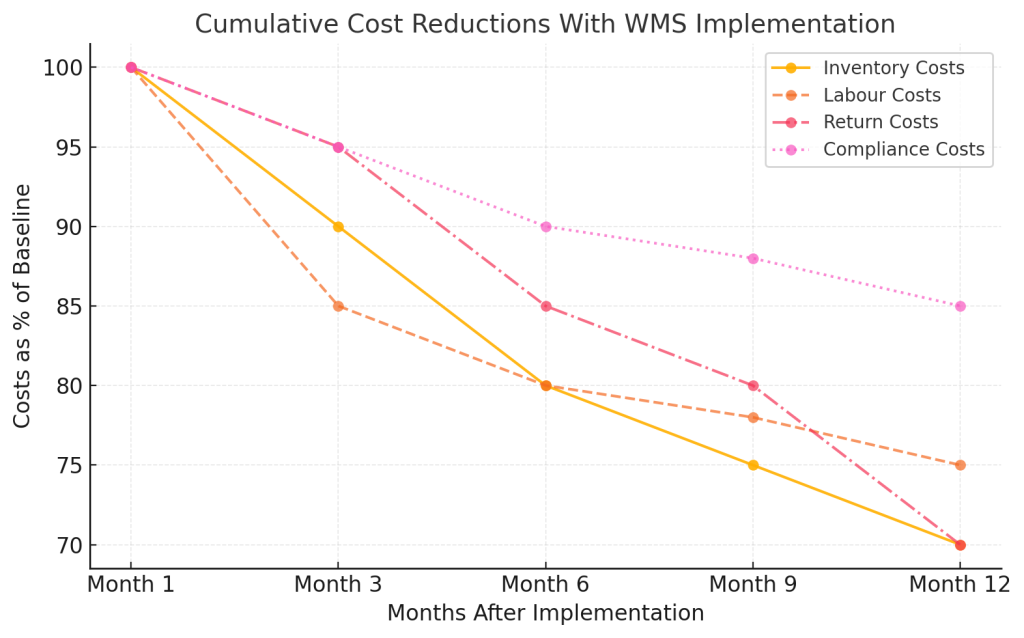

Beyond labour efficiency, a Warehouse Management System (WMS) drives cost reductions across multiple operational facets, including inventory management, order accuracy, and compliance. These features not only enhance day-to-day operations but also position businesses for sustainable long-term growth. By minimising stock discrepancies and optimising inventory turnover, a WMS ensures that businesses maintain the right levels of stock while reducing carrying costs. Additionally, improved order accuracy reduces returns and enhances customer satisfaction, leading to increased loyalty and repeat business over time.

Inventory Management Cost Savings

WMS optimises inventory levels by providing real-time tracking and actionable insights. With tools like automated replenishment alerts and demand forecasting, businesses can maintain just the right amount of stock, reducing storage costs and eliminating losses from overstocking or stockouts. Efficient inventory control also minimises waste, particularly for perishable goods, saving significant costs. Furthermore, accurate inventory data enables better supplier negotiations and improved order planning, enhancing the overall supply chain efficiency. By leveraging these insights, businesses can respond swiftly to market changes, ensuring they remain competitive and financially resilient.

Return Management and Customer Satisfaction

Returns are an inevitable part of warehousing operations, but they don’t have to be a cost burden. WMS automates the returns process, including authorisations, inventory updates, and restocking workflows. This reduces the resources needed to handle returns while improving the customer experience—a win-win for businesses. By streamlining these processes, a WMS ensures that returned items are quickly inspected and re-entered into inventory, minimising delays and reducing the risk of lost sales. Additionally, enhanced visibility into return trends allows businesses to identify patterns, enabling better product management and informed decision-making to reduce future return rates.

Comprehensive Cost Optimisation With WMS

| Operational Area | Cost-Saving Mechanism | Impact |

|---|---|---|

| Inventory Management | Real-time tracking, demand forecasting, and automated replenishment alerts. | Lower storage costs and reduced stock wastage. |

| Returns Handling | Automated workflows for returns, restocking, and inventory updates. | Reduced labour costs and enhanced customer satisfaction. |

| Compliance and Reporting | Tools to ensure regulatory adherence and generate audit-ready reports. | Avoidance of fines and improved operational transparency. |

| Order Accuracy | Enhanced picking and packing accuracy through barcode/RFID integration. | Lower returns and fewer customer complaints. |

| Energy Efficiency | Optimised workflows and automation reduce warehouse energy consumption. | Lower utility bills and a more sustainable operation. |

Conclusion: WMS as a Game-Changer for Cost Efficiency

A Warehouse Management System isn’t just a tool for operational optimisation—it’s a strategic solution for reducing costs and driving profitability. From labour savings and inventory optimisation to automation and compliance, WMS enables businesses to achieve more with fewer resources. For Australian businesses facing unique logistical challenges, implementing a WMS is an investment in efficiency, scalability, and long-term growth.

With clear, measurable benefits, WMS empowers businesses to remain competitive in a fast-evolving market while meeting customer expectations with precision. If operational cost savings are your goal, a WMS should be at the core of your strategy. By implementing a robust WMS, you can not only enhance efficiency but also drive innovation throughout your supply chain, positioning your business for long-term success. For more insights on how a WMS can transform your operations, visit WHM Software.