Introduction

In industries ranging from food and beverage to pharmaceuticals and cosmetics, maintaining strict control over lot tracking and expiration dates is essential for product quality, regulatory compliance, and customer safety. Effective lot control ensures you can trace every batch of product from raw materials to finished goods, quickly isolate defects, and execute precise recalls if necessary. Similarly, monitoring expiration dates prevents spoiled or outdated items from reaching customers and impacting your brand reputation. In this comprehensive guide, you’ll learn best practices for implementing lot tracking and expiration date management in your operations—covering labeling, processes, software, and regulatory considerations.

Why Lot Tracking and Expiration Management Matter

Ensuring Product Safety and Quality

- Traceability: Lot codes link finished products back to specific production runs and raw-material sources.

- Recall readiness: In the event of contamination or defect, you can pinpoint and recall only affected lots, minimizing waste and risk.

- Shelf-life integrity: Expiration tracking prevents the sale of degraded or unsafe products, protecting consumers and avoiding liability.

Regulatory Compliance

- FDA, USDA, EU Falsified Medicines Directive: Many agencies mandate lot-level traceability for pharmaceuticals, food, and medical devices.

- Audit trails: Detailed records of lot movements and expiration status demonstrate due diligence during inspections.

Operational Efficiency

- Inventory rotation: First-Expired, First-Out (FEFO) ensures you sell items nearing expiration first, reducing spoilage loss.

- Demand planning: Visibility into upcoming expirations helps sales and procurement teams manage promotions and reorder timing.

Establishing a Lot Tracking System

1. Define Your Lot Code Structure

Lot codes must be unique, human‐readable, and encode key information such as production date, line, or shift. A common format is:

cssCopyEdit[YYYYMMDD]-[Line]-[Batch#]

Example: 20250715-L2-017

- YYYYMMDD: Production date

- L2: Manufacturing line or facility

- 017: Sequential batch number

2. Integrate Lot Recording at Each Stage

- Receiving: Record supplier lot numbers when raw materials arrive.

- Production: Assign and print finished‐goods lot codes immediately after packaging.

- Warehousing: Scan each pallet or SKU into your warehouse management system (WMS) along with its lot code.

- Shipping: Verify outbound lot codes against customer orders to ensure correct batches ship.

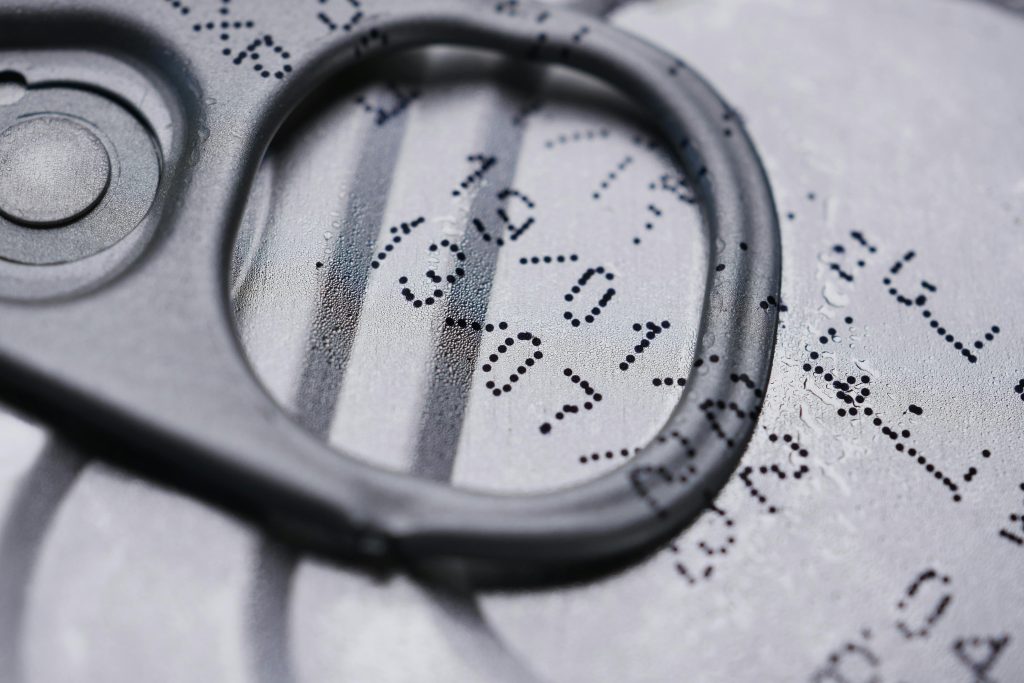

3. Labeling Best Practices

- Clear, durable labels: Use barcode or QR code labels that withstand handling and environmental conditions.

- Redundancy: Print both human‐readable text and machine‐readable codes.

- Placement: Ensure labels are consistently placed (e.g., top‐right corner of cartons) for quick scanning.

Managing Expiration Dates Effectively

1. Establish Shelf-Life Parameters

Determine the “best‐by” or “use‐by” durations for each product based on stability testing, regulatory guidelines, and supplier recommendations.

2. Automate Expiration Date Capture

- ERP or WMS Integration: Configure your system to automatically calculate expiration dates from batch production dates plus defined shelf‐life.

- Label generation: Embed the expiration date directly on the lot label (e.g.,

EXP: 2026-01-14).

3. Implement FEFO Inventory Rotation

- Warehouse practices: Organize racks by earliest expiration dates on the front, using pick‐face zones for speedy access.

- Scanning checks: At each pick, require a scan of the lot label to verify that the chosen unit has the earliest expiration.

Leveraging Technology for Traceability

1. Warehouse Management Systems (WMS)

- Lot-number tracking: Mandate scanning of lot codes on receiving, putaway, picking, and shipping.

- Expiration alerts: Automatically flag lots nearing expiration (e.g., within 30 days) for review or promotion.

2. Enterprise Resource Planning (ERP)

- Integrated bill of materials (BOM): Link raw‐material lots to finished‐goods lots to maintain complete traceability.

- Batch recall module: Enable rapid lookup of all products containing a specific raw‐material lot.

3. Serialized Tracking and Blockchain (Advanced)

- Serialization: Assign a unique identifier to each individual unit—useful in pharmaceuticals where unit‐level recall may be required.

- Blockchain: Some organizations leverage distributed ledgers to share immutable lot histories with supply‐chain partners.

Regulatory and Audit Considerations

1. Maintain Detailed Records

- Receiving logs: Supplier, date, and lot numbers of all raw materials.

- Production logs: Lot assignments, quantities produced, and production parameters.

- Movement logs: Every transfer, pick, ship event scanned with timestamp and operator ID.

2. Conduct Regular Audits

- Physical audits: Periodically cycle‐count lot quantities and verify expiration dates on‐shelf.

- System audits: Review electronic records for missing or inconsistent lot entries, and reconcile with physical logs.

3. Prepare for Recalls

- Recall procedure: Document step‐by‐step actions for isolating and retrieving affected lots.

- Communication plan: Pre‐draft customer and supplier notifications to accelerate response times.

Best Practices and Common Pitfalls

| Best Practice | Pitfall to Avoid |

|---|---|

| Standardize lot code formats across facilities | Multiple lot formats that confuse scanning and reporting |

| Scan at every touchpoint | Relying on manual entry, leading to transcription errors |

| Set automated expiration warnings | Ignoring alerts and letting expiring products sit on shelf |

| Train staff on lot‐handling procedures | Assuming everyone knows the process, causing inconsistencies |

| Integrate WMS, ERP, and QA systems | Siloed systems with disconnected lot information |

Conclusion

Implementing robust lot tracking and expiration date management is crucial for product safety, regulatory compliance, and operational efficiency. By standardizing lot codes, automating expiration calculations, enforcing FEFO rotation, and leveraging integrated WMS/ERP technologies, you gain full visibility into your inventory’s provenance and shelf life. Regular audits, clear recall procedures, and staff training ensure that when issues arise, you can respond swiftly and accurately—protecting both consumers and your brand. Adopt these best practices to turn lot and expiration management from a regulatory burden into a competitive advantage.