The warehouse management industry is evolving rapidly, driven by technological advancements and changing supply chain dynamics. As businesses adapt to new challenges, several trends are reshaping how warehouses operate. Here’s a look at the key trends expected to define warehouse management in 2025. Increased adoption of artificial intelligence and machine learning is enhancing automation, improving decision-making, and optimizing inventory control. Additionally, the rise of sustainable warehousing practices is driving the implementation of energy-efficient systems and eco-friendly packaging solutions.

AI and Automation in Warehouse Operations

Artificial intelligence (AI) and automation are revolutionising warehouse management by streamlining operations, reducing errors, and improving efficiency. AI-powered tools enable smarter decision-making, predictive analytics, and optimised workflows, while automation technologies like robotics, autonomous vehicles, and conveyor systems handle repetitive tasks with precision. These innovations not only enhance order accuracy and fulfillment speed but also reduce labour costs by minimizing manual intervention. Furthermore, real-time AI-driven insights help warehouses adapt to fluctuating demand, ensuring optimal resource allocation and continuous process improvement. As we look ahead, these advancements are key components of the Warehouse Management Trends 2025, driving the industry towards greater agility and effectiveness.

Why It Matters:

- AI improves inventory accuracy with demand forecasting and real-time tracking.

- Automation reduces labour costs and improves order fulfilment speed.

- Robotic pick-and-pack systems minimise errors and increase productivity.

Sustainability in Supply Chain and Warehousing

With increasing pressure to adopt sustainable practices, warehouses are focusing on energy efficiency and waste reduction. Green logistics, solar-powered facilities, and eco-friendly packaging solutions are becoming essential components of warehouse operations. Implementing these sustainable practices not only helps reduce the carbon footprint but also enhances brand reputation among environmentally conscious consumers. Additionally, leveraging data analytics allows warehouses to monitor energy consumption and waste production, enabling continuous improvement and cost savings over time. As sustainability becomes a priority, these initiatives are critical to staying competitive in the evolving Warehouse Management Trends 2025 landscape.

Why It Matters:

- Reducing energy consumption lowers operational costs and carbon footprints.

- Sustainable supply chain practices enhance brand reputation and meet regulatory requirements.

- Waste minimisation contributes to a circular economy.

Key Technological Trends in Warehouse Management

| Trend | Impact | Examples |

|---|---|---|

| AI in Warehouse Management | Improves inventory accuracy, demand forecasting, and workflow efficiency. | Predictive analytics, real-time inventory updates. |

| Automation and Robotics | Handles repetitive tasks and improves order fulfilment speed. | Autonomous vehicles, robotic picking systems. |

| Green Logistics | Promotes sustainability and reduces energy consumption. | Solar-powered warehouses, eco-friendly packaging. |

| Cloud-Based WMS | Enables remote access and real-time updates across multiple locations. | Scalable software-as-a-service (SaaS) solutions. |

| Blockchain Technology | Ensures supply chain transparency and enhances data security. | Tamper-proof records for shipments and transactions. |

The Rise of Cloud-Based WMS and Blockchain Technology

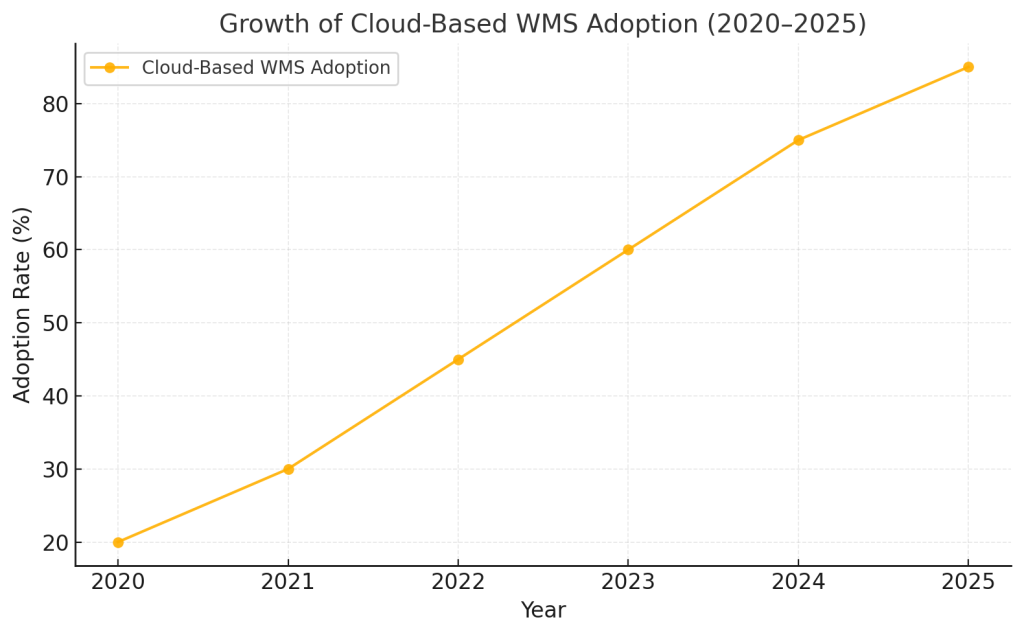

Cloud-based Warehouse Management Systems (WMS) and blockchain technology are becoming indispensable for modern warehouses. These innovations provide enhanced flexibility, scalability, and security, reshaping how supply chains function globally. By facilitating real-time data sharing and collaboration among stakeholders, cloud-based solutions improve transparency and responsiveness throughout the supply chain. Furthermore, blockchain technology ensures the integrity of transaction records, enabling secure tracking of products and reducing the risk of fraud or discrepancies in inventory management. As these technologies gain traction, they play a crucial role in driving the Warehouse Management Trends 2025, empowering businesses to operate more efficiently and sustainably.

Cloud-Based WMS for Scalability

Cloud-based WMS solutions allow businesses to manage operations remotely, integrate data across multiple warehouses, and scale effortlessly as operations grow. These systems reduce reliance on on-premises infrastructure, enabling faster deployments and real-time visibility. Additionally, they facilitate seamless collaboration among teams, allowing for quicker response times to market changes and customer demands. By leveraging cloud technology, businesses can also benefit from automatic updates and enhancements, ensuring they always have access to the latest features and security measures.

Why It Matters:

- Simplifies multi-warehouse management with centralised data.

- Reduces IT costs and ensures automatic updates.

- Enhances collaboration across teams and locations.

Blockchain Technology for Supply Chain Transparency

Blockchain’s ability to create tamper-proof records makes it ideal for supply chains, ensuring transparency, traceability, and enhanced trust. Warehouses leveraging blockchain can track goods at every stage of the supply chain, improving accountability and reducing fraud. This technology also streamlines communication between parties by providing a single source of truth, eliminating discrepancies and misunderstandings. Furthermore, the integration of smart contracts within blockchain systems automates processes such as payments and order fulfillment, leading to increased efficiency and reduced operational costs.

Why It Matters:

- Increases visibility in complex supply chains.

- Builds consumer trust with transparent product origins.

- Simplifies compliance with regulatory requirements.

Final Trends: AI in Logistics and Last-Mile Innovations

As warehouse management continues to evolve, artificial intelligence (AI) and last-mile delivery innovations are set to play pivotal roles in shaping the future. These advancements address some of the most pressing challenges in supply chain management, such as efficiency, accuracy, and customer satisfaction. By utilizing AI algorithms for route optimization and predictive analytics, businesses can enhance delivery speed and reduce costs, ensuring a seamless experience for customers.

AI-Driven Logistics Optimisation

AI is transforming logistics by enabling smarter decisions through predictive analytics, machine learning, and real-time data processing. In warehouse management, AI enhances inventory control, demand forecasting, and route optimisation, leading to reduced costs and improved operational efficiency. Moreover, AI-driven insights empower managers to proactively identify trends and potential disruptions, allowing for agile adjustments to maintain seamless operations and meet customer expectations.

Why It Matters:

- Predictive analytics minimise stockouts and overstocking.

- AI-powered tools optimise routes, reducing fuel costs and delivery times.

- Machine learning improves accuracy in order picking and packing.

Last-Mile Delivery Innovations

The last mile is often the most expensive and inefficient segment of the supply chain. Innovations like autonomous delivery vehicles, drone deliveries, and localised fulfilment centres aim to streamline last-mile logistics, ensuring faster and more cost-effective deliveries. By leveraging technology to enhance route planning and optimize delivery schedules, businesses can significantly reduce delivery times and improve customer satisfaction in this critical phase of the logistics process.

Why It Matters:

- Autonomous vehicles reduce reliance on human drivers.

- Drones make deliveries faster in urban and rural areas.

- Localised fulfilment centres enable same-day or next-day delivery options.

Future Innovations in Warehouse Management

| Innovation | Impact | Example |

|---|---|---|

| AI-Powered Demand Forecasting | Reduces waste and ensures optimal stock levels. | Machine learning tools predicting seasonal trends. |

| Autonomous Delivery Vehicles | Lowers delivery costs and improves last-mile efficiency. | Electric delivery vans with AI-based navigation. |

| Drone Deliveries | Enables rapid delivery in urban and remote areas. | Amazon Prime Air’s drone delivery program. |

| Smart Sensors and IoT | Provides real-time monitoring of warehouse conditions and inventory levels. | IoT-enabled smart shelves and tracking devices. |

| Localised Fulfilment Centres | Shortens delivery times and enhances customer satisfaction. | Micro-warehouses in densely populated areas. |

Conclusion: Preparing for the Future of Warehouse Management

The future of warehouse management lies in embracing cutting-edge technologies that prioritise efficiency, sustainability, and customer satisfaction. From AI and automation to blockchain and last-mile innovations, these trends are not just reshaping warehouses—they’re transforming the entire supply chain. For businesses looking to stay ahead in this evolving landscape, exploring solutions from WHM Software can provide the tools needed to optimise operations and enhance overall performance at WHM Software.

For businesses to stay competitive in 2025 and beyond, adopting these technologies will be crucial. Whether it’s leveraging AI to optimise inventory or using drones for faster deliveries, the key to success lies in integrating these advancements strategically. By doing so, warehouses can drive growth, reduce costs, and deliver unmatched value to customers.