What is the Difference Between Inventory Management and Warehouse Management?

When running a business that involves physical goods, it’s crucial to have efficient systems in place to manage your stock and organize your storage. Two key processes that often get confused are inventory management and warehouse management. While both are essential in supply chain operations, they serve different functions and focus on different aspects of your business. To optimize these processes, using the right warehouse management software can make a significant difference in improving efficiency and organization. In this blog post, we’ll discuss the core differences between inventory management and warehouse management and why both are vital to the smooth running of your business.

What is Inventory Management?

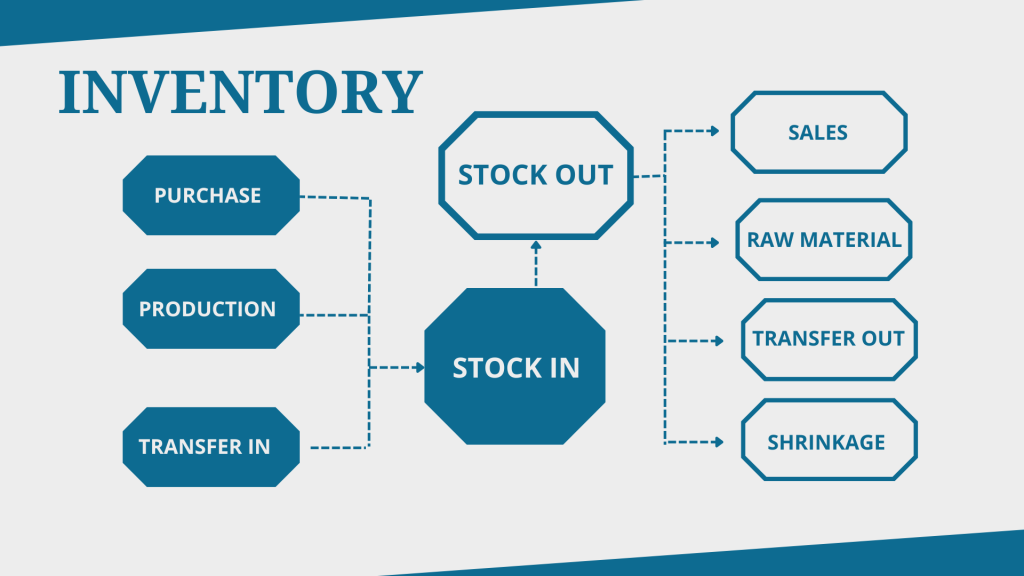

Inventory management refers to the systematic approach to sourcing, storing, and selling inventory—whether that be raw materials, components, or finished products. The ultimate goal is to ensure a business has the right amount of inventory at the right time, preventing both stockouts and overstock situations. With a well-executed inventory management system, businesses can keep their operations running smoothly, reduce excess costs, and maintain customer satisfaction by ensuring product availability.

Some of the key functions involved in inventory management include:

- Stock Tracking: Keeping track of products at all stages, from procurement to storage and eventually sale. This includes monitoring stock quantities, tracking product movement, and updating the system with every transaction.

- Demand Forecasting: Predicting future product demand based on historical data and market trends, allowing businesses to adjust their stock levels accordingly.

- Order Management: Ensuring that orders are processed efficiently and that customers receive the correct products on time.

- Stock Replenishment: Knowing when to reorder products before stock runs out, ensuring there is no disruption in the business flow.

An effective inventory management system often uses technology, such as inventory management software, to track products and automate these processes.

What is Warehouse Management?

Warehouse management refers to the activities and processes associated with managing a warehouse or distribution center. Unlike inventory management, which focuses on tracking product quantities, warehouse management is more concerned with the physical storage and movement of goods within a warehouse. A warehouse management system (WMS) helps streamline this process by organizing product locations, optimizing picking and packing strategies, and ensuring products are stored and shipped efficiently.

Key components of warehouse management include:

- Storage Optimization: Warehouse management involves designing the layout of the warehouse to make the most of available space, ensuring goods are easy to locate and access.

- Order Picking: This is the process of selecting items from the warehouse shelves to fulfill customer orders. Picking can be manual or automated, depending on the technology used in the warehouse.

- Receiving and Shipping: Warehouse management includes overseeing the inbound and outbound movement of goods, ensuring that stock arrives at the right time and is dispatched quickly and accurately.

- Inventory Control: Ensuring that the items stored in the warehouse are accurately reflected in inventory records. This includes tracking stock levels and preventing discrepancies between physical inventory and recorded inventory.

A well-run warehouse plays a crucial role in maintaining business efficiency and ensuring products reach customers quickly and accurately.

Key Differences Between Inventory Management and Warehouse Management

Although both systems involve products, the roles they play in the supply chain are distinct. Below are the key differences between inventory management and warehouse management:

Focus Area

- Inventory Management: The primary goal of inventory management is to ensure that businesses maintain optimal stock levels. This involves tracking the movement of goods, replenishing stock, and ensuring the right products are available to meet customer demand.

- Warehouse Management: Warehouse management, on the other hand, deals with the physical storage and handling of goods within a warehouse. It includes optimizing the use of warehouse space, ensuring products are easily accessible, and improving the efficiency of order fulfillment.

Scope of Operations

- Inventory Management: Inventory management covers the entire supply chain, from ordering products to forecasting demand and replenishing stock.

- Warehouse Management: Warehouse management focuses solely on managing the warehouse itself, ensuring products are received, stored, picked, and shipped properly.

Technology Used

- Inventory Management: Businesses use inventory management software (IMS) to track stock levels, manage orders, and automate reorder processes. These tools often integrate with other business systems like accounting and sales platforms.

- Warehouse Management: Warehouse management relies on a Warehouse Management System (WMS), which helps optimize warehouse operations, improve picking and packing accuracy, and monitor real-time stock movement.

Impact on Business Operations

- Inventory Management: Efficient inventory management directly impacts the financial health of a business. By preventing overstocking or stockouts, it helps companies reduce storage costs and ensure products are available when customers want them.

- Warehouse Management: Warehouse management impacts the operational efficiency of a business. By optimizing space and improving order fulfillment speed, it can enhance overall productivity and reduce lead times.

How Inventory Management and Warehouse Management Work Together

While inventory management and warehouse management are distinct processes, they are closely intertwined and work together to ensure smooth supply chain operations. For instance:

- Inventory Management depends on accurate data from the warehouse, such as stock levels and the movement of goods. Without real-time visibility into warehouse operations, inventory management systems cannot function properly.

- Warehouse Management needs inventory data to efficiently allocate storage space, track orders, and manage the flow of goods in and out of the warehouse. Without a well-functioning inventory management system, warehouses may experience discrepancies between physical stock and recorded stock.

By integrating these two systems, businesses can achieve end-to-end visibility, reduce operational costs, improve customer satisfaction, and make data-driven decisions.

Why is Understanding the Difference Important for Your Business?

A business must understand the key differences between inventory management and warehouse management to implement effective strategies that improve overall performance. Here’s why:

- Cost Savings: By managing inventory effectively and ensuring efficient warehouse operations, businesses can reduce unnecessary storage costs, minimize waste, and prevent product shortages.

- Customer Satisfaction: Accurate inventory management and efficient warehouse operations ensure that products are available when customers need them, leading to higher customer satisfaction and repeat business.

- Better Decision Making: Knowing the differences allows business owners and managers to make informed decisions about inventory levels, warehouse layouts, and supply chain strategies that ultimately benefit the business.

Conclusion

In conclusion, while inventory management and warehouse management both play critical roles in a business’s supply chain, they have different focuses. Inventory management revolves around tracking stock, forecasting demand, and maintaining the right levels of inventory. Warehouse management, on the other hand, focuses on the physical handling and storage of products within the warehouse.

Understanding these distinctions and integrating the two systems is essential for businesses that deal with physical goods. By managing both inventory and warehouse operations effectively, businesses can reduce costs, improve operational efficiency, and provide better service to customers.

To optimize your supply chain and enhance your overall business performance, it’s essential to understand the interplay between inventory management and warehouse management.